Like completely different firms, poultry manufacturing faces challenges, along with cash circulation, inflation, monetary downturns, and market volatility. No matter all these fastened challenges and variations, poultry firms keep worthwhile. Nonetheless, it is always important to undertake methodologies to optimize productiveness and profitability.

Frequent advice to maximise productiveness, profitability, and monetary sustainability is to boost effectivity, reduce waste, deal with costs, evaluation pricing, and improve infrastructure in the long term.

Feed is a really highly effective subject affecting manufacturing costs and sustainability constructions worldwide.

- The most effective method to chop again feed costs is through feed formulation.

- Least-cost feed formulation primarily based totally on linear programming reduces costs nonetheless would not keep in mind maximizing enterprise profitability.

ISSUES WITH LEAST-COST FEED FORMULATION

Least-cost feed formulation has moreover consolidated the idea that nutrient ranges are mounted, obtained from Tables or Breeder Guides, making them an absolute requirement.

- These “nutrient requirements” for poultry are values determined for max natural effectivity in various neutral experiments. Which suggests a most of three nutritional vitamins have been determined beneath comparable circumstances.

- Nonetheless, profit-maximizing energy and nutrient ranges are solely acknowledged as quickly as an econometric analysis is made for each market and manufacturing website.

In all probability essentially the most worthwhile nutrient ranges may probably be variable, counting on changes in feedstuff worth and worth of the poultry merchandise to advertise (reside birds, carcasses, cut-up parts, eggs in shell or egg mass).

A typical topic with least-cost feed formulation is that when the prices of protein sources like soybean meal rise, the mathematical decision tends to chop again dietary amino acid density to amass cheaper feed.

- Nonetheless, broilers are delicate to amino acid consumption.

- At lower amino acid ranges, they may dictate a lower progress value, yield, elevated feed conversion ratio, and reduce income, reducing profitability.

Then once more, profitability is also decreased if the similar dietary nutrient density is maintained when the poultry closing product worth reduces. Rooster stocking density and shutting market weight may even affect the optimum dietary nutrient densities to maximise profitability.

ALTERNATIVES TO LEAST-COST FEED FORMULATION

As an alternative of making an attempt solely at least worth, a further relevant technique is to make use of feed formulation to maximise income. Feed formulation to maximise margin or income could make use of nonlinear programming, laptop fashions linked to optimizers, or a combination of every methods.

- Nonlinear programming permits for the inclusion of income equation(s) in its place of a set desired nutrient density.

- This suggests the desired nutrient ranges are selected the time of feed formulation in its place of using pre-established “nutrient requirements.”

The income equation is perhaps obtained by changing into a quadratic curve between feeding worth per unit of obtain or income over feed worth versus energy, nutritional vitamins, and ingredient ranges. These curves are fitted to purchase the function that may produce the monetary optimums as energy or nutrient ranges vary. Quadratic equations might be utilized, nonetheless completely different mathematical options is also further relevant or right to swimsuit this experimental and econometric info.

- This technique requires buying info on animal responses to each energy, main nutrient, and even foremost feed ingredient ranges.

- Nonetheless, these responses vary with environmental circumstances and, over time, with the evolution attributable to fastened genetic selection.

- Then, buying data from classical dose-response experiments is simply not sustainable anyway.

Dadalt et al. (2015) in distinction linear and nonlinear formulations to feed broilers stocked at two densities. A extreme stocking density (HDH) with 14 chickens/m2 and a low density (LDH) with 10 chickens/m2 had been evaluated. Every formulation methods promoted comparable broiler effectivity. Nonetheless, the high-density feed using linear formulation decreased physique weight in 42-day-old males, nonetheless not when nonlinear formulation was used.

- The non-linear feed formulation at LDH yielded the perfect feed conversion ratio values and the underside worth/kg broiler for every sexes.

- The outcomes demonstrated that the feed formulation system that yields the most effective effectivity or lowest feed conversion ratio is simply typically basically essentially the most worthwhile.

Almeida et al. (2019) moreover evaluated the value of non-linear programming for laying hens beneath three market eventualities. They in distinction it with diets formulated with linear programming following nutrient requirement options of the Brazilian Tables, the genetic stress ideas, or mathematical fashions to maximise effectivity.

- These feed formulation methods did not have an effect on Haugh unit, albumen prime, or exterior egg prime quality parameters.

- Nonetheless, feed formulation affected yolk weight, albumen weight, yolk shade, yolk proportion, albumen proportion, and effectivity parameters.

The outcomes of these outcomes will not be talked about proper right here due to the home obtainable, nonetheless usually, feeds formulated using linear programming primarily based totally on dietary requirements obtained by mathematical fashions and the genetic stress handbook promoted greater effectivity outcomes on account of these feeds had been nutritionally denser.

Nonetheless, the treatments or feed formulations that maximized reside effectivity did not result in elevated profitability. The utmost profitability was obtained with the burden loss plan formulated for a optimistic market state of affairs using non-linear programming, which usually maintained the utmost profitability beneath each state of affairs.

In conclusion, non-linear programming is a tool to maximise profitability.

- Nonetheless, info is required to calculate the fowl’s response to energy and nutrient ranges beneath numerous circumstances, making it troublesome to amass most of the time by empirical observations or experiments. These estimations is perhaps obtained with mathematical fashions.

NUTRITIONAL MODELING IN POULTRY NUTRITION TO MAXIMIZE PROFIT

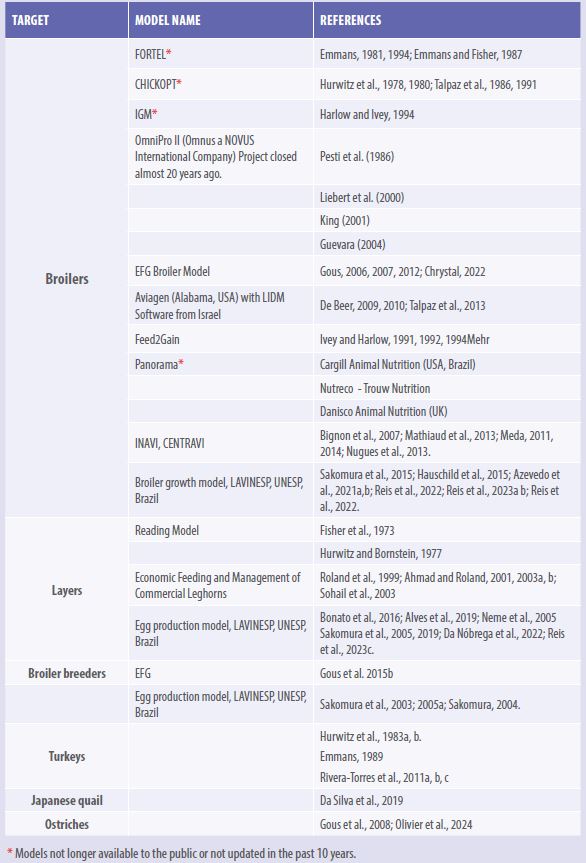

Quite a few tutorial evaluation groups and a number of other different private companies, paying homage to NOVUS Worldwide, Cargill, Aviagen, and Trouw Weight loss program, have proposed various fashions. Lots of these fashions mustn’t longer obtainable as a consequence of their low commerce adoption or on account of they weren’t updated.

Desk 1 displays an entire nonetheless not exhaustive guidelines of the printed mathematical fashions that had been or are publicly accessible and have implications for poultry weight loss program optimization.

- Some fashions use a set of equations primarily based totally on empirical evaluation obtained with large datasets.

- In distinction, completely different fashions are mechanistic primarily based totally on concept and evaluation designed to estimate nutrient utilization and deposition parameters in its place of solely observing animal effectivity.

- A number of of those fashions included an econometric half or module looking for to optimize profitability and reduce environmental affect barely than solely maximize animal effectivity.

Considered one of many foremost factors that has restricted its implementation, validation, evaluation, and extra progress has been the need for further education on model progress and utilization for smart nutritionists.

The restricted understanding of these fashions’ concepts and powerful scientific basis comes from the slim visualization of the multitude of disaggregated scientific publications all by way of various a few years with out references to hyperlink them to express model progress.

- Fashions primarily based totally on empirical evaluation or assortment of observations with out looking for explanatory parts have transform outdated and underutilized.

- Mechanistic fashions that describe the first parts inflicting a response proceed to be developed and might be utilized with the model new genotypes whereas bettering prediction accuracy.

Most mechanistic fashions at current are mounted or make use of a single widespread price, representing the everyday fowl in a gaggle. Stochasticity or potential variability is carried out by simulating various events the potential distribution of the inhabitants or by altering basically essentially the most very important parts inflicting variability.

- The EFG Software program program and the AVINESP fashions are two of basically essentially the most well-developed fashions.

- These fashions share comparable theoretical or conceptual sides nonetheless differ in some estimation methodologies and terminology.

Gerry Emmans, Colin Fisher, and Rob Gous from South Africa developed the EFG fashions for broilers, broiler breeders, turkeys, and swine. Presently, solely the EFG broiler and pig progress fashions might be discovered. Dr. Nilva Okay. Sakomura directed the occasion of the AVINESP fashions on the State School of São Paulo in Jaboticabal, Brazil.

The AVINESP fashions have been developed for various species: broilers, broiler breeders, pullets, laying hens, and quails. AVINESP has broiler and layer fashions obtainable to most of the people.

These two mechanistic fashions are primarily based totally on the hypothesis developed by Gerry Emmans and collaborators in Scotland.

- This concept signifies that right mathematical descriptions of animal genotypes and genetic progress potential are necessary to determining energy and nutrient requirements in any animal species.

- Right mathematical descriptions of egg manufacturing are moreover important for determining nutritional vitamins primarily based on the stage of egg manufacturing and egg mass.

The EFG and AVINESP mechanistic fashions had been developed with a logical assortment of modules to predict metabolizable energy (ME), web energy (NE), amino acids (AA), calcium and phosphorus needs to fulfill progress and egg manufacturing targets.

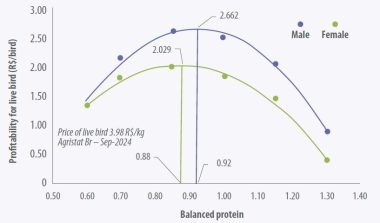

- The equations that describe the utilization of energy and nutritional vitamins have been printed and described. Examples of their talent to predict optimum ranges of amino acids to maximise profitability relying within the market goals have been printed.

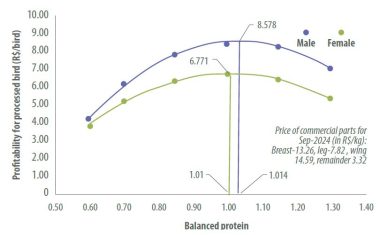

- In Figures 1 and a few, readers can observe the variations in calculations to estimate the extent of balanced protein required to maximise profitability.

- We nonetheless desire a larger understanding of metabolic processes and efficiencies for nutrient utilization or the affect of various environmental, dietary, and antinutritional parts and feed parts.

- When using fashions, it is necessary to needless to say solely the everyday fowl is simulated. The inhabitants distribution of the flocks should be included to make the outcomes related to enterprise circumstances.

- Digital sensor experience, intensive info analysis, and machine learning can improve the accuracy of mechanistic fashions.

There is a consensus that modeling is further sustainable for conducting poultry weight loss program evaluation. It has transform a extremely efficient gadget for optimizing nutrient excretion and maximizing profitability for further sustainable poultry manufacturing.

The 2024 NASEM report on “Nutrient Requirements” of Poultry (10th revised model) actually useful that academia develop mathematical fashions. Nonetheless, the NASEM committee report did not deal with the necessary econometric aspect that should be included in poultry weight loss program.

- Nonetheless, poultry fashions that the commerce could think about are already obtainable, as a result of the reader can observe inside the data supplied proper right here.

- The options obtained inside the validation of these fashions will assist to boost their precision and accuracy.

- Nonetheless, adopting these new methodologies for feed formulation inside the poultry commerce is as necessary as rising fashions.

- Consequently, as beforehand indicated, further data and education are compulsory on this topic, and we hope this textual content contributes to this knowledge.

Provide: avinews.com